Roller coasters are among the most iconic and thrilling attractions in amusement parks around the world. Their creation combines art, engineering, and physics to deliver excitement, safety, and unforgettable experiences.

As one of China’s leading amusement ride manufacturers, Carnee Rides specializes in designing and producing world-class roller coasters for theme parks, resorts, and entertainment centres globally. In this guide, we’ll take you through the complete process—from concept design to final construction and testing—and explain what makes these giant machines so fascinating.

1. The Origin and Evolution of Roller Coasters

While roller coasters are now symbols of modern engineering, their roots stretch back centuries. The first versions emerged in 15th-century Russia, where people rode sledges down icy wooden ramps—an early prototype of the thrill ride.

In 1827, America’s first gravity-powered railway—the Mauch Chunk Switchback Railway in Pennsylvania—was used to transport coal but soon became a passenger attraction. Later, innovators like LaMarcus Adna Thompson and Phillip Hinkle transformed this idea into dedicated amusement rides, giving birth to the first true roller coasters at Coney Island in the late 1800s.

Today, roller coasters are feats of advanced technology—reaching heights over 450 feet and speeds beyond 120 mph—yet they’re still driven by the same principles: gravity, inertia, and brilliant engineering.

2. The Design Process: From Concept to Blueprint

Every great roller coaster begins with an idea—a vision of how riders should feel: thrilled, terrified, or joyfully weightless. Designing a roller coaster involves both creativity and precise science.

2.1 Choosing the Types of Roller Coaster

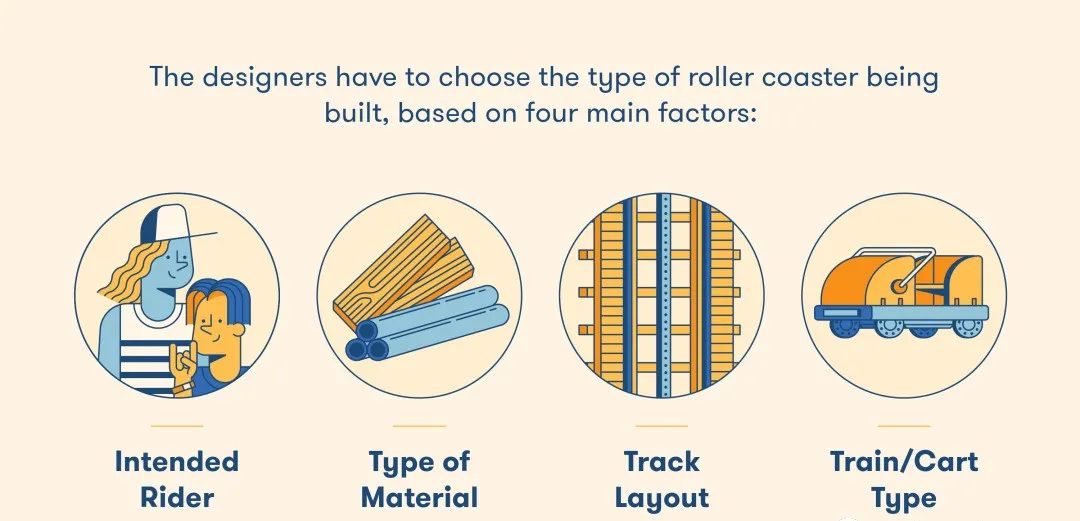

Selecting the right coaster type is the first and most crucial step. The type determines the materials, layout, speed, and cost of the final ride.

Key factors include:

- Target Audience:

Family-friendly coasters use smoother slopes and moderate speeds. High-intensity rides for teenagers and adults feature sharp drops, inversions, and vertical loops. - Material:

- Wooden Coasters: Classic charm, bouncy feel, traditional aesthetics.

- Steel Coasters: Smooth, flexible, capable of inversions and complex loops.

- Train Design: From side-friction trains (like early Leap-the-Dips models) to modern suspended coasters (like Batman: The Ride).

- Track Layout: Spiral, figure-eight, out-and-back, or looping layouts shape the overall experience.

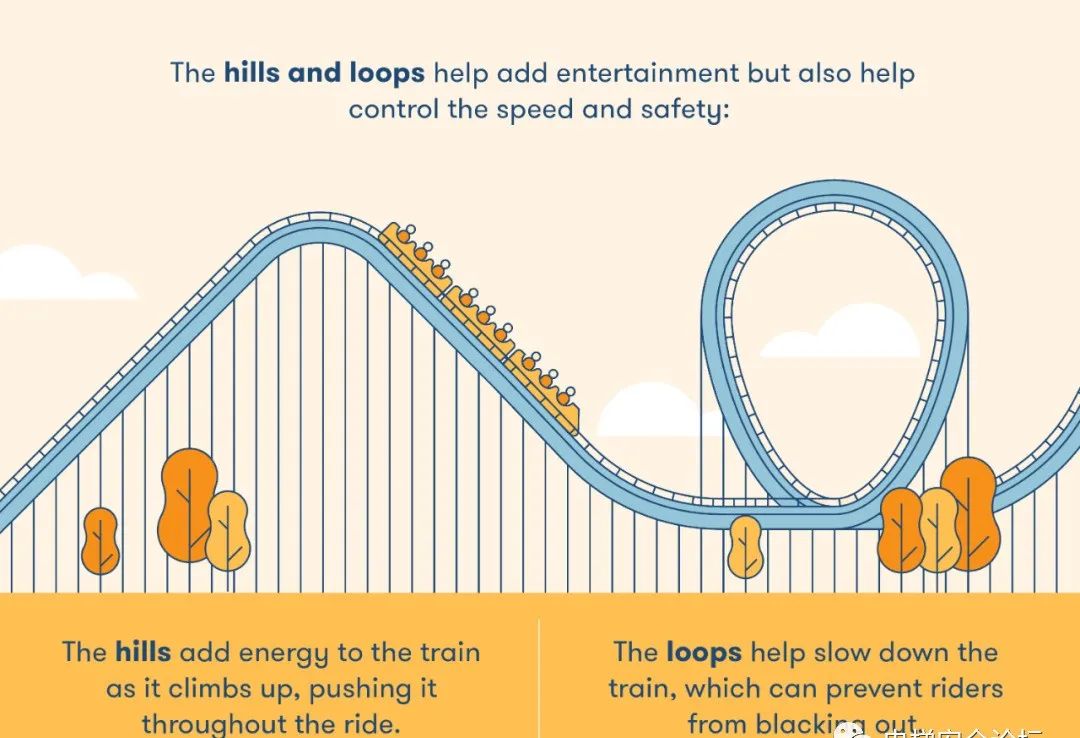

2.2 Designing the Track Layout

The roller coaster track layout defines the rhythm and excitement of the ride. Engineers carefully calculate height, speed, and angle to maintain balance between thrill and safety.

| Element | Purpose | Example |

| Lift Hill | Builds potential energy for the ride | First and tallest hill |

| Loop (Clothoid) | Provides inversion and g-force balance | Vertical loop |

| Helix | Adds centrifugal thrill | Corkscrew turns |

| Brake Run | Controls speed safely | End of the track |

These elements are precisely modeled using CAD software, ensuring that every curve and slope maintains rider comfort and mechanical integrity.

2.3 Engineering and Simulation

Before a single piece of steel is bent, the entire coaster is digitally simulated. Engineers test:

- G-force tolerance

- Speed consistency

- Energy conversion efficiency

- Passenger comfort

- Emergency braking and safety sensors

Roller coaster engineers also perform stress tests on track geometry and support beams to ensure long-term durability.

At Carnee Rides, engineers combine decades of experience with advanced simulation software to deliver designs that are both exhilarating and compliant with international safety standards.

3. Construction: Building the Roller Coaster

Once design approval is complete, the manufacturing and construction phase begins. It’s where engineering turns into reality.

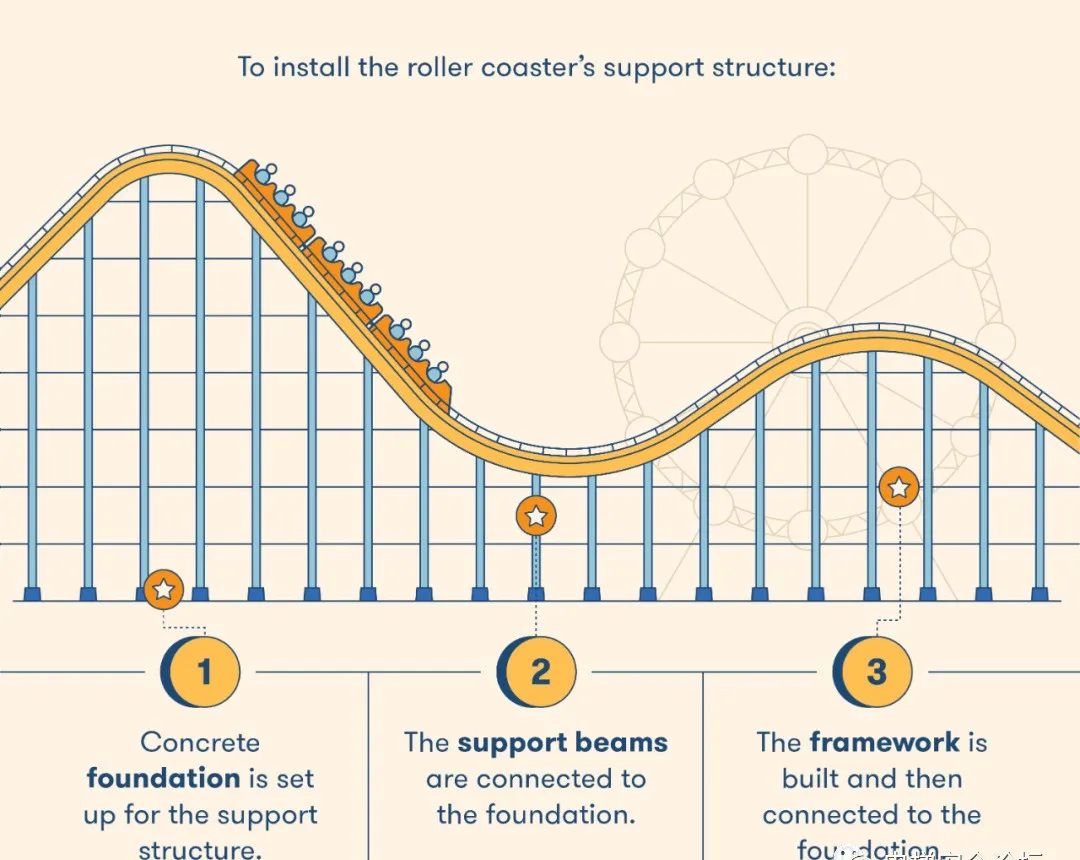

3.1 Site Preparation

Before any structure rises, the construction site is cleared and leveled. Foundations are marked precisely according to the blueprint. Depending on soil conditions:

- Concrete foundations are poured for stability.

- In sandy terrain, wooden piles are driven deep for extra support.

Accuracy is critical—even a few millimeters off can affect the entire track alignment.

3.2 Manufacturing and Installing the Support Structure

The support structure forms the skeleton of the coaster.

| Material | Process | Description |

| Wooden Coaster | On-site cutting and assembly | Beams bolted together using treated timber |

| Steel Coaster | Prefabricated in factory | Welded tubular sections shipped and assembled with cranes |

Each segment is labeled and installed sequentially using cranes. Engineers check vertical and horizontal alignment after every section to prevent track stress.

3.3 Installing the Track System

After the support structure is set, the track is installed on top.

- Wooden tracks are laminated from multiple layers of planks and reinforced with steel plates.

- Steel tracks arrive in curved sections that are bolted and welded together for smooth, continuous rides.

Safety features include:

- Up-stop wheels to prevent derailing.

- Guide wheels to maintain lateral stability.

- Anti-rollback devices to secure cars during climbs.

For detailed insight, see How Do Roller Coasters Stay on Track?.

3.4 Launch Systems and Brakes

Modern roller coasters use advanced launch and braking systems instead of engines.

Main Launch Systems:

- Chain Lift: Traditional system powered by motors and chains.

- Linear Induction / Synchronous Motor (LIM/LSM): Uses electromagnetic propulsion.

- Hydraulic Launch: Pushes cars using pressurized fluid.

- Pneumatic Launch: Uses compressed air for a quick boost.

Braking Systems:

- Trim Brakes: Adjust speed at intervals.

- Block Brakes: Stop trains completely for spacing and safety.

4. Testing, Safety, and Quality Control

Safety is at the heart of roller coaster engineering. Before any ride opens to the public, it goes through extensive testing and certification.

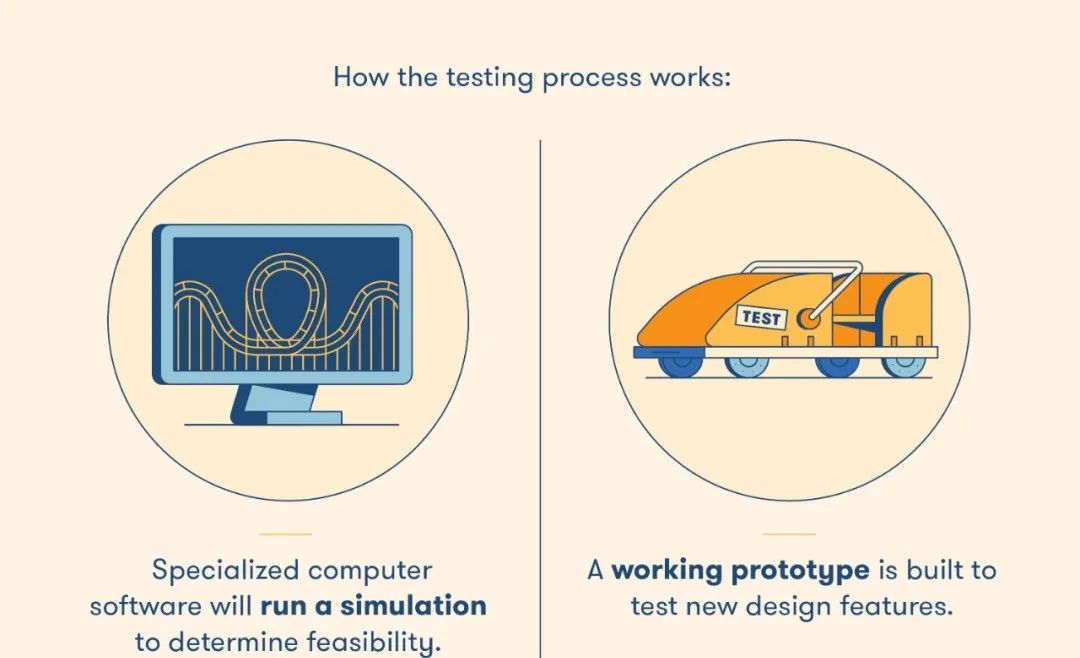

4.1 Simulation & Prototype Testing

Engineers first run digital simulations to confirm all calculations. Then, a prototype or test track may be built to measure physical forces and confirm real-world performance.

4.2 Test Runs & Inspection

After installation, test cars loaded with sandbags are sent through multiple cycles. Sensors measure:

- Speed consistency

- Structural vibrations

- G-force on seats

- Brake responsiveness

Daily inspections continue even after launch to ensure ongoing safety.

According to statistics, serious roller coaster injuries are extremely rare—about 1.2 per million rides.

Learn more about design safety and standards in our Roller Coaster FAQ Guide.

5. Cost, Customization & Manufacturing Expertise

The cost of building a roller coaster varies widely depending on size, materials, and complexity. Small family rides may cost tens of thousands, while mega coasters can exceed several million dollars.

For a detailed breakdown, read How Much Does a Roller Coaster Cost?.

Carnee Rides offers customized roller coaster design and manufacturing solutions—from compact park models to large-scale thrill rides. Each project includes:

- Structural design & CAD modeling

- Factory fabrication

- On-site installation support

- After-sales maintenance & technical training

As one of the Top 10 Roller Coaster Manufacturers, Carnee Rides is trusted by global clients for quality, safety, and innovation.

6. Conclusion

Roller coasters are not just amusement rides—they’re a blend of physics, artistry, and engineering mastery. From the early wooden switchbacks to today’s steel giants, the process of making them combines creativity, precision, and passion.

At Carnee Rides, we take pride in crafting roller coasters that inspire joy and wonder—rides that are safe, reliable, and thrilling for generations of park visitors.

FAQs About How Roller Coasters Are Made

✅ Want to customize your own roller coaster project?

Contact Carnee Rides, one of China’s leading roller coaster manufacturers, to discuss your theme park design, capacity, and theme requirements.

Explore our wide range of roller coasters for sale — from family-friendly roller coasters to high-thrill steel roller coasters — and bring your park’s next signature attraction to life.